Drip edge flashings are an essential component in roofing systems, providing a protective barrier that directs water away from the roof deck and fascia. Proper installation is crucial for preventing moisture infiltration, which can lead to rot, mold, and structural damage. This guide offers professional insights into installing drip edge flashings correctly, ensuring longevity and optimal performance for your roofing projects.

Understanding the Importance of Drip Edge Flashings

Before diving into the installation process, it’s vital to comprehend the role of drip edge flashings. These metal strips are installed along the edges of the roof, creating a finished look while safeguarding the underlying materials. They prevent water from seeping under the roofing components, thereby protecting the fascia board and roof deck from water damage. Utilizing high-quality drip edge flashings is fundamental to achieving a durable roofing system.

Selecting the Right Materials

Choosing the appropriate drip edge flashing material is the first step toward a successful installation. Common materials include galvanized steel, aluminum, and copper. Galvanized steel is known for its strength and durability, making it a popular choice among professionals. Aluminum is lightweight and resistant to corrosion, while copper offers exceptional longevity and a distinctive aesthetic appeal. Opting for standard 10′ long drip edge flashings reduces the number of seams, minimizing potential leak points and ensuring a smoother installation process.

Preparation and Safety Measures

Before beginning the installation, ensure that all necessary tools and materials are on hand. This includes drip edge flashings, roofing nails, a hammer or nail gun, tin snips for cutting the metal, and appropriate safety equipment. Inspect the roof deck for any signs of damage or rot, addressing any issues before proceeding. Safety is paramount; always use proper fall protection when working at heights and adhere to Occupational Safety and Health Administration (OSHA) guidelines.

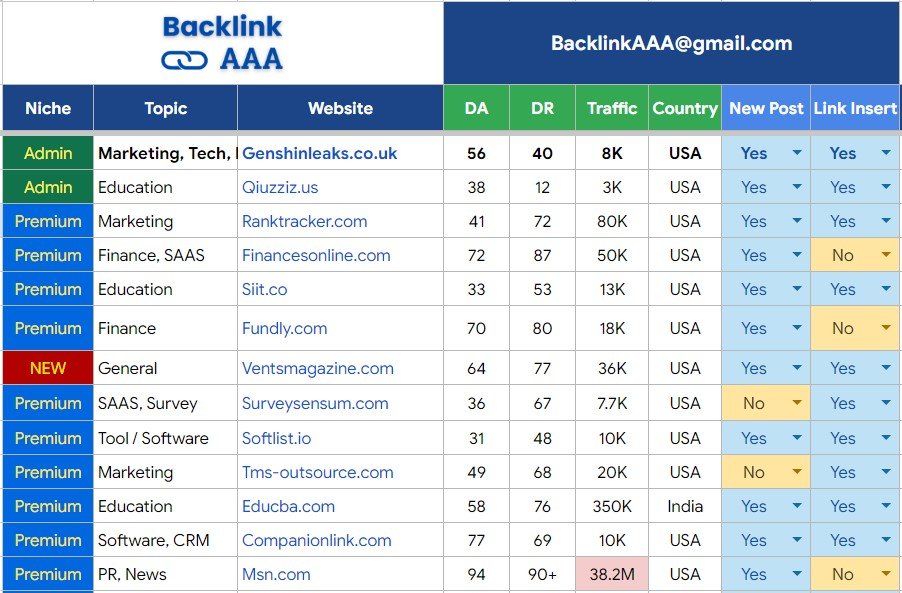

Read more: https://genshinleaks.co.uk/is-fraser-siding-a-good-brand/

Installing Drip Edge Flashings at the Eaves

Start the installation at the eaves of the roof. Position the drip edge flashing so that the shorter, horizontal leg rests atop the roof deck, while the longer, vertical leg extends over the fascia board. This configuration ensures that water flows away from the fascia and into the gutters. Secure the drip edge with roofing nails, spacing them approximately every 12 inches. Be sure to nail high enough on the drip edge so that the nails will be covered by the roofing material, preventing exposure to the elements.

When joining two pieces of drip edge flashing, overlap them by at least 2 inches. This overlap should be in the direction of water flow to prevent moisture from seeping between the joints. Using 10′ long drip edge flashings minimizes the number of overlaps needed, enhancing the overall integrity of the installation.

Applying Underlayment and Shingles

After the drip edge flashing is installed at the eaves, lay the roofing underlayment over the drip edge. This positioning allows any water that penetrates the shingles to be directed onto the drip edge and away from the roof deck. Install the shingles according to the manufacturer’s specifications, ensuring they extend slightly beyond the drip edge to facilitate proper water runoff.

Read more: https://genshinleaks.co.uk/how-to-check-whether-a-home-exterior-contractor-is-trustworthy/

Installing Drip Edge Flashings on the Rakes

For the roof’s rakes (the sloped edges), the installation sequence differs slightly. Install the roofing underlayment first, extending it over the edge of the roof deck. Then, place the drip edge flashing over the underlayment. This method prevents wind-driven rain from getting under the drip edge and into the roof assembly. Secure the flashing with nails, following the same spacing and overlap practices as with the eaves.

Attention to Corners and Valleys

Special care is needed when installing drip edge flashings at roof corners and valleys. For corners, miter the flashing to create a clean, tight fit that maintains the protective barrier. In valleys, ensure that the drip edge does not interfere with the valley flashing. Proper coordination between these components is essential to prevent leaks and water damage.

Final Inspection and Quality Assurance

Once installation is complete, conduct a thorough inspection of the drip edge flashings. Check for any gaps, loose nails, or misalignments that could compromise the roofing system’s effectiveness. Ensuring that the drip edge is properly installed not only enhances the roof’s performance but also contributes to a professional appearance that reflects high-quality workmanship.

Compliance with Building Codes and Manufacturer Guidelines

Adhering to local building codes and manufacturer recommendations is crucial. Building codes often specify requirements for drip edge installation, including material types, dimensions, and fastening methods. Manufacturers of drip edge flashings provide guidelines that, when followed, ensure the product performs as intended and may be necessary to maintain warranty coverage.

Conclusion

Proper installation of drip edge flashings is a fundamental aspect of professional roofing. By selecting quality materials, following best practices, and paying attention to details, you can significantly enhance the durability and effectiveness of the roofing system. Investing time in correct installation not only protects the structure but also upholds the standards of excellence expected in the industry.

For premium materials and expert support, consider partnering with a reputable drip edge flashings producer. Their products and expertise can provide the assurance needed to execute installations with confidence and precision.